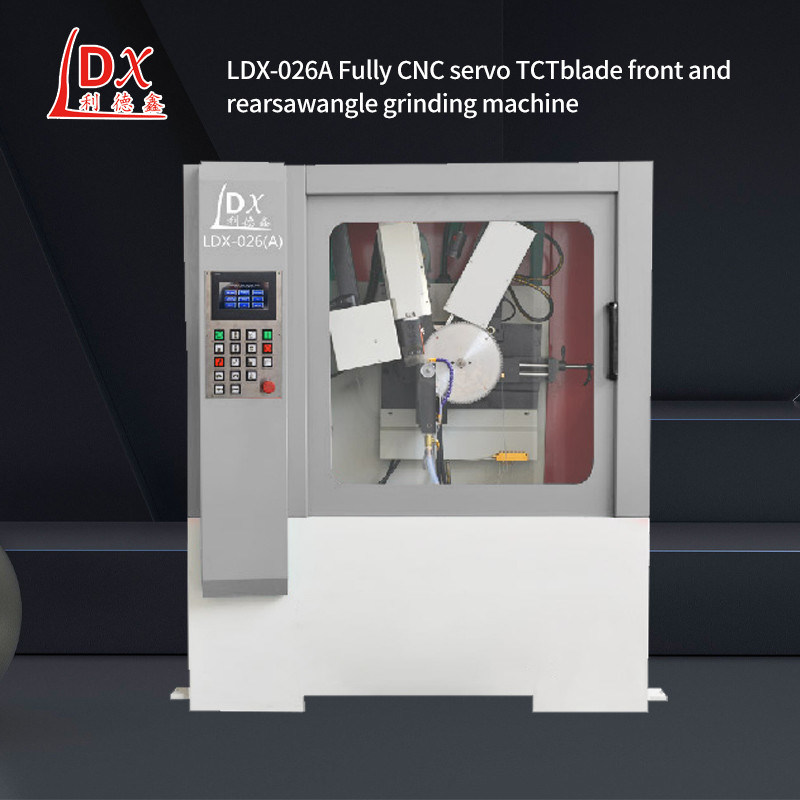

LDX-026A Completely Enclosed CNC Circular Saw Blade Front And Rear Angle Grinding Machine

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-026A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Mechanical size (length X width X height): 1500X1300X1800mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Inner Bore Of Saw Blade: | ¢10-220mm | Negative Chamfer Grinding: | -27° |

|---|---|---|---|

| Grinding Head Rotation Angle: | Grinding Head Rotation Angle: 90° And 180° | Grinding Speed:: | 26m/s |

| Tooth Face Angle: | 5°~+30° | Appearance(Long*Width*Height):: | 1500X1300X1800mm |

| Highlight: | Rear Angle Grinding Machine,Saw Blade Rear Angle Grinding Machine |

||

Product Description

LDX-026A Completely Enclosed CNC Circular Saw Blade Front And Rear Angle Grinding Machine

Things to pay attention to when using alloy saw blade grinding machine:

1,the coolant grinding is determined by the grinding fluid

2,Influence of gear grinding mechanism on gear grinding

3,Welding factors.

4,Influence of grinding wheel quality and grain size width.

TCT circular saw blade automatic gear grinding machine error compensation is reliable?

1,Choose a reliable brand of automatic gear grinding machine to ensure that the equipment itself has high precision and stable performance.

2,Regular maintenance and maintenance of the equipment to ensure the normal operation of the error compensation system.

3,The operator should receive professional training to understand the working principle and operation method of the error compensation system to avoid affecting its performance due to improper operation, in general, the error compensation function of the alloy circular saw blade automatic gear grinding machine is reliable in most cases, but the user still needs to pay attention to the maintenance and operation specifications of the equipment to ensure its long-term stable performance.

| Main Technical Parameters : |

| Range of external diameter of processing:¢100-¢800mm |

| Inner bore of saw blade:¢10-220mm |

| Thickness of saw web (steel plate):1-8mm |

| Pitch range:7-100mm |

| Tooth face angle:5°~+30° |

| Tooth top dorsal angle:6-45° |

| Tooth left/right gradient: Tooth top/tooth face 45° |

| Cutter grinding stroke range: Max. 25mm (adjustable) teeth/min |

| Grinding speed:0.5-6mm/s |

| Working speed: Max. 20 teeth/min |

| Grinding wheel dimensions (outer diameter * bore): (¢125mm*¢32mmX1mm) |

| Negative chamfer grinding: -27° |

| Grinding head rotation angle: 90° and 180° |

| Grinding speed: 26m/s |

| Coolant pump flux:501/min |

| Coolant cylinder volume: 85L |

| Total power: 2.2KW |

| Voltage:three-phase 380v |

| Total weight of equipment:900KG |

| Appearance(Long*Width*Height):1500X1300X1800mm |

| Technical features: |

| This machine is designed in reference to the features of domestic and foreign similar types, which absorbs and analyzes the advantages of the same type and improves the functions to some extent at the same time. |

| 1. Preset many groups of tooth types and one-key multifunctional operation. |

| 2. Trapezoid flat teeth can be finished at a time, features CNC grinding and arbitrary tooth types, and can improve the efficiency by 3 times; due to the adoption of improved tooth extraction operation, the accuracy is improved, and |

![]()

![]()

![]()