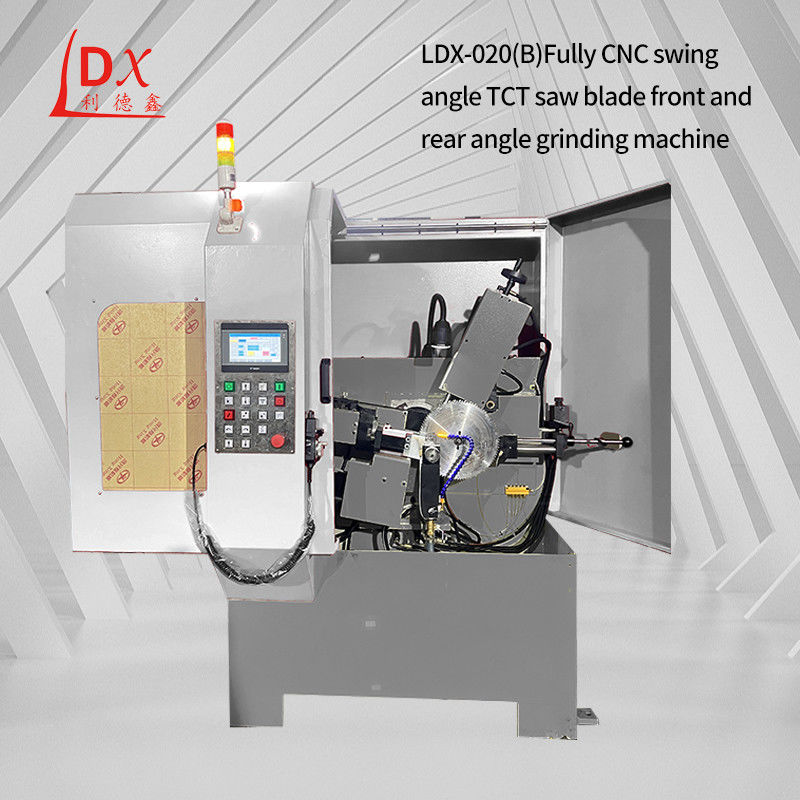

LDX-020B Fully CNC Saw Blade Front And Rear Angle Grinding Machine Manufacturer

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-020(B) |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Mechanical size (length X width X height): 1500X1300X1800mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Mechanical Weight: | 700KG | Negative Chamfer Grinding: | -27° |

|---|---|---|---|

| Grinding Wheel Line Speed: | 26m/s | Coolant Pump Flow: | 501/min |

| Saw Blade Thickness (steel Plate): | 1-10mm | Tooth Surface Angle: | 5 Degrees ~ +30 Degrees |

| Processing Saw Blade Diameter Range: | ¢100-800mm | ||

| Highlight: | Fully CNC Saw Blade Grinding Machine,Rear Angle Saw Blade Grinding Machine,Front Angle Saw Blade Grinding Machine |

||

Product Description

LDX-020B Fully CNC Saw Blade Front And Rear Angle Grinding Machine Manufacturer

What do you need to pay attention to when grinding teeth:

1,The coated teeth on the tool head are different from the usual circular saw blades, and the grinding method is different, please pay special attention to it.

2,After grinding, please confirm whether the tool head is still off, defective, unground places, which will cause poor cutting or injury.

3,Saw blade reprocessing (reaming) is recommended not to exceed the original hole 20mm, otherwise it will cause detensioning and the cutting effect of the saw blade will be affected.

How to sharpen saw blades, how to sharpen TCT saw blades:

1,Generally, saw blades can be divided into two categories: straight tooth grinding and oblique grinding teeth. The characteristic of straight tooth grinding is that the saw teeth are long, short, wide and narrow. The saw tooth surface is horizontal and easy to grind. The bevel grinding teeth are separated on the left and right, and the sawtooth surface has a certain slope.

2,If it is mechanical automatic grinding, it is easy to operate as long as the machine is adjusted well. Manual grinding requires certain techniques. During the grinding process, pay attention to the consistent grinding progress, otherwise the length of the saw teeth will appear, which is not conducive to cutting.

3,The angle of the bevel grinding teeth needs to be consistent with the angle of the original saw blade. During the grinding process, it is necessary to skip grinding. After one side is completed, flip over and grind the other side. The smaller the angle of the sawtooth bevel, the sharper the cutting and the smaller the propulsion force, but the workpiece is prone to burrs. The larger the bevel angle, the more difficult the propulsion force, but the smoother the cutting surface of the workpiece.

4,Saw blades can be divided into: diamond saw blades for stone cutting; high-speed steel saw blades for metal material cutting (without inlaid carbide blades); used for solid wood, furniture, artificial panels, aluminum alloys, and aluminum profiles Carbide saw blades for cutting , radiators, plastics, plastic steel, etc.

| Technical Parameters: |

| Processing saw blade diameter range: ¢100-800mm |

| Saw blade aperture: ¢10-220mm |

| Saw blade thickness (steel plate): 1-7mm |

| Pitch: 7-100mm |

| Tooth surface angle: 5 degrees ~ +30 degrees |

| Tip back angle: 6-45 degrees |

| Left and right inclination of the tooth: tooth top / tooth surface 45 degrees |

| Sharpening stroke range: up to 25mm (adjustable) teeth / minute |

| Sharpening speed: 0.5-6mm/s |

| Working speed: maximum 20 teeth / minute |

| Grinding wheel size (outer diameter x hole): (¢125mmx¢32mmX1mm) |

| Negative chamfer grinding: -27 degrees |

| Grinding head can rotate angle: 90 degrees and 180 degrees |

| Grinding wheel line speed: 26m / s |

| Coolant pump flow: 501/min |

| Cooling tank volume: 85L |

| Total power: 1.85 kW |

| Voltage: three-phase 380v |

| Mechanical weight: 710KG |

| Mechanical size (length X width X height): 1500X1300X1800mm |

| Technical features: |

| This machine is designed in reference to the features of domestic and foreign similar types, which absorbs and analyzes the advantages of the same type and improves the functions to some extent at the same time. |

| 1. Preset many groups of tooth types and one-key multifunctional operation. |

| 2. Trapezoid flat teeth can be finished at a time, features CNC grinding and arbitrary tooth types, and can improve the efficiency by 3 times; due to the adoption of improved tooth extraction operation, the accuracy is improved, and the service life is prolonged. |

![]()

![]()