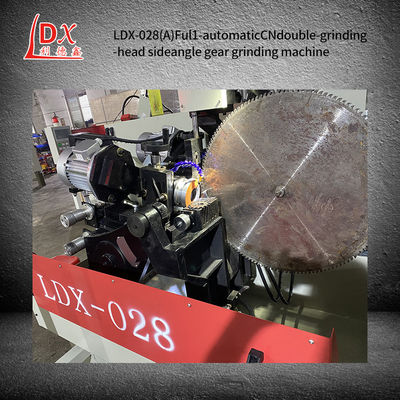

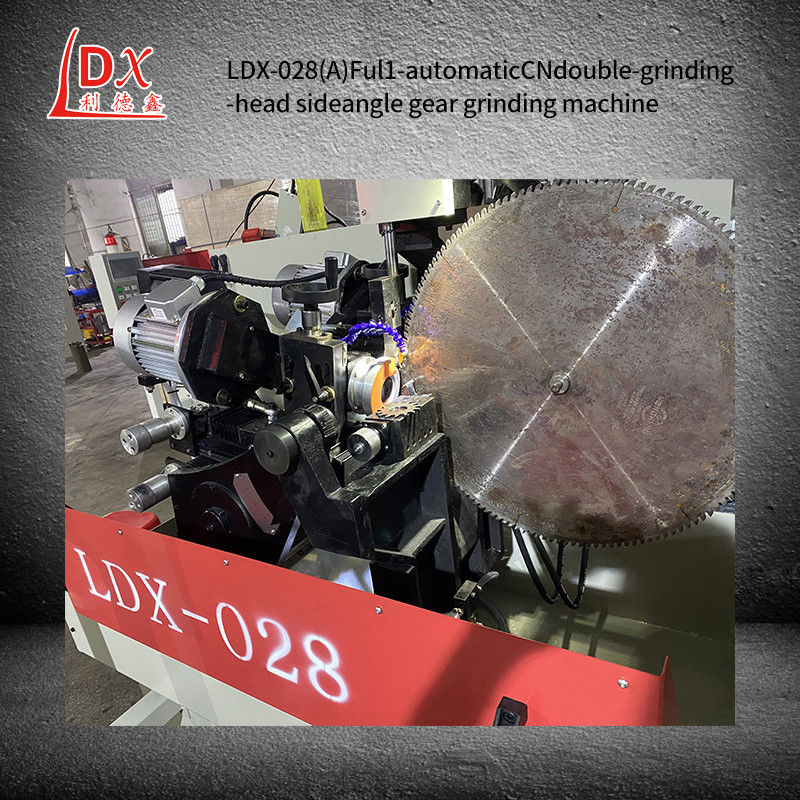

LDX-028A Servo Full CNC Alloy Saw Blade Double Grinding Head Side Grinding Machine

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-028A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | USB |

| Packaging Details: | Outer diameter dimensions: 1.75*1.4*2.0mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Tooth Pitch: | 5-80mm | Coolant Pump Flux: | 501/min |

|---|---|---|---|

| Voltage: | Three-phase 380v | Thickness Of Saw Web (steel Plate): | 1-7mm |

| Saw Web Machining Diameter Range: | ¢100-¢800mm | Radial Angle: | 3°-15° |

| Highlight: | CNC Alloy Saw Blade Grinding Machine,Alloy Saw Blade Grinding Machine |

||

Product Description

LDX-028A Servo Full CNC Alloy Saw Blade Double Grinding Head Side Grinding Machine

Band saw blade grinding machine manufacturers talk about error compensation is reliable:

1,The fuzzy clustering regression method is used to optimize the temperature variables of the machine tool. The radial thermal error compensation model of grinding wheel and workpiece shaft is established based on the principle of multiple linear regression and minor square method.

2,After analysis, the compensation accuracy of the radial thermal error model of the grinding wheel and the workpiece shaft and the relative error of the measured value are both lower than 2.000%, which indicates that the curve of the compensation model is well fitted and the compensation accuracy is high.

3,The thermal error compensation model can effectively reduce the tooth surface error and improve the overall machining accuracy (ISO) of the tooth surface by more than 3 degrees, thus verifying the accuracy and reliability of the model.

Reduced blade loss and replacement frequency:

1,By precisely controlling the grinding process, the automatic gear grinding machine can ensure the accuracy and consistency of the saw blade grinding, reducing the loss of the saw blade caused by improper grinding.

2,Improved grinding quality means that the service life of the saw blade is extended, which reduces the frequency of blade replacement and reduces material costs.

3,The circular saw blade automatic gear grinding machine automates the grinding process, significantly reducing the need for manual gear grinding and thus reducing labor costs.

| Technical parameters: |

| Saw web machining diameter range:¢100-¢800mm |

| Saw web bore diameter: 12-220mm |

| Thickness of saw web (steel plate):1-7mm |

| Tooth pitch: 5-80mm |

| Front inclination angle, inclination angle: 5°-15° |

| Radial angle: 3°-15° |

| Operating speed: 18 teeth/min |

| Feeding stroke: 1-28mm (stepless variable speed) |

| Grinding wheel dimensions: 80*100*32mm |

| Grinding speed: 26m/s |

| Coolant pump flux: 501/min |

| Coolant cylinder volume: 90L |

| Total power: 4.3KW |

| Voltage: Three-phase 380v |

| Weight: 1,100KG |

| Outer diameter dimensions: 1.75*1.4*2.0mm |

| Technical characteristics: |

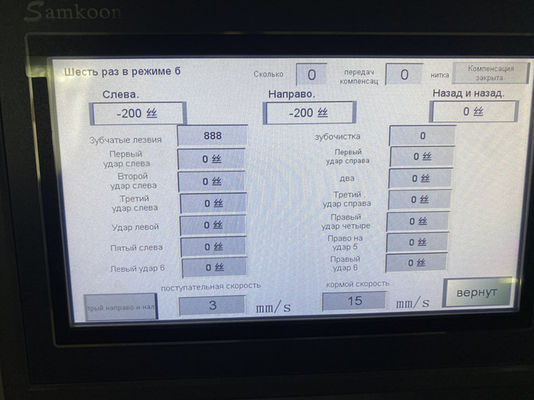

| An intuitive and simple whole Chinese operation interface is matched with a large-sized touch screen, so the equipment is easier to operate, and all preset procedures or self-compiled procedures are more convenient to call; the servo tool setting device features accurate positioning, so the product grinding accuracy is greatly ensured. Due to the adoption of high-quality and high-accuracy castings and machined parts, the service life of the equipment is greatly prolonged, and the equipment is simple and easy to operate and maintain; one person can operate many pieces of equipment at the same time, so the production efficiency is greatly improved, and the cost is reduced. |

![]()

![]()

![]()

![]()