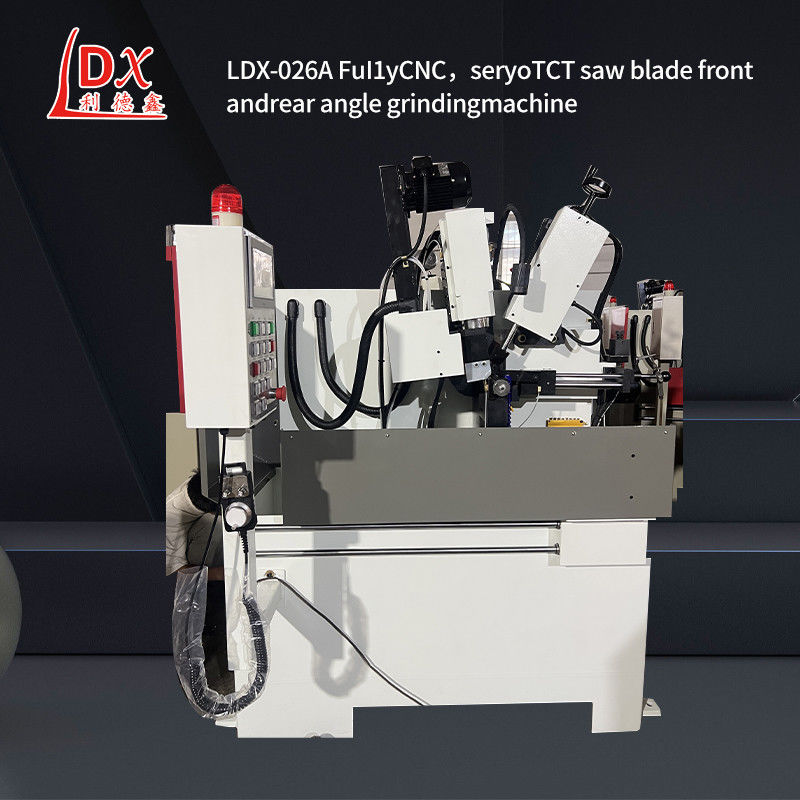

LDX-026A Guangdong Automatic Circular Saw Blade Before And After Angle Grinding Machine Factory Wholesale

Product Details:

| Place of Origin: | Foshan, Guangdong |

| Brand Name: | lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-026A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Appearance(Long*Width*Height):1600X1300X2000mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Range Of External Diameter Of Processing: | ¢100-¢800mm | Inner Bore Of Saw Blade: | ¢10-220mm |

|---|---|---|---|

| Pitch Range: | 7-100mm | Tooth Face Angle: | 5°~+30° |

| Tooth Top Dorsal Angle: | 6-45° | ||

| Highlight: | Automatic Circular Saw Blade Grinding Machine,Guangdong Circular Saw Blade Grinding Machine |

||

Product Description

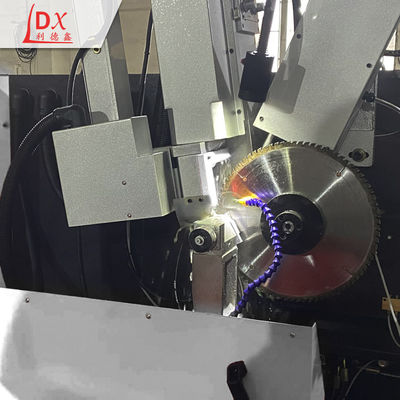

LDX-026A TCT circular saw blade grinding machine automatic grinding machine manufacturers

Pay attention to the following points when operating the saw blade grinding machine:

1,Feed speed of grinding head.

2,The feed rate of grinding head, the selection of grinding wheel particle size is very important to the feed rate.

3,Tooth extraction mechanism can not be ignored. Regardless of the structure of the gear grinding machine, the accuracy of the tooth coordinates is designed to the quality of the sharpening tool, and the tooth needle is pressed in a reasonable position on the tooth surface when adjusting the machine, and it is also extremely critical to remove the tooth, the tooth claw should be flexible and reliable.

Correct operation of the machine:

1,Select the appropriate grinding wheel and grinding fluid.

2,Pour the cutting fluid into the reservoir of the machine.

3,Place the circular saw blade on the gear grinding machine and secure it.

4,Power on the machine and follow the grinding procedure.

5,Keep the circular saw blade stable during grinding to ensure that it does not fall off or move.

6,Depending on the need, fine-tuning of tooth adjustment buttons, grinding wheel thickness and claw drop points may be required to ensure grinding quality and efficiency.

| Main Technical Parameters : |

| Range of external diameter of processing:¢100-¢800mm |

| Inner bore of saw blade:¢10-220mm |

| Thickness of saw web (steel plate):1-8mm |

| Pitch range:7-100mm |

| Tooth face angle:5°~+30° |

| Tooth top dorsal angle:6-45° |

| Tooth left/right gradient: Tooth top/tooth face 45° |

| Cutter grinding stroke range: Max. 25mm (adjustable) teeth/min |

| Grinding speed:0.5-6mm/s |

| Working speed: Max. 20 teeth/min |

| Grinding wheel dimensions (outer diameter * bore): (¢125mm*¢32mmX1mm) |

| Negative chamfer grinding: -27° |

| Grinding head rotation angle: 90° and 180° |

| Grinding speed: 26m/s |

| Coolant pump flux:501/min |

| Coolant cylinder volume: 85L |

| Total power: 2.2KW |

| Voltage:three-phase 380v |

| Total weight of equipment:900KG |

| Appearance(Long*Width*Height):1500X1300X1800mm |

| Technical features: |

| This machine is designed in reference to the features of domestic and foreign similar types, which absorbs and analyzes the advantages of the same type and improves the functions to some extent at the same time. |

| 1. Preset many groups of tooth types and one-key multifunctional operation. |

| 2. Trapezoid flat teeth can be finished at a time, features CNC grinding and arbitrary tooth types, and can improve the efficiency by 3 times; due to the adoption of improved tooth extraction operation, the accuracy is improved, and the service life is prolonged. |

![]()

![]()

![]()