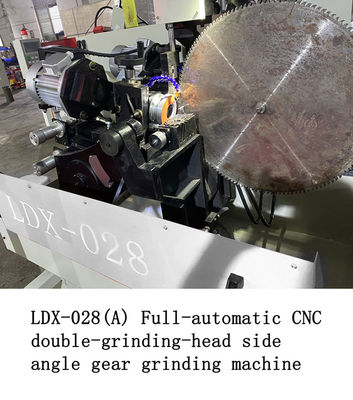

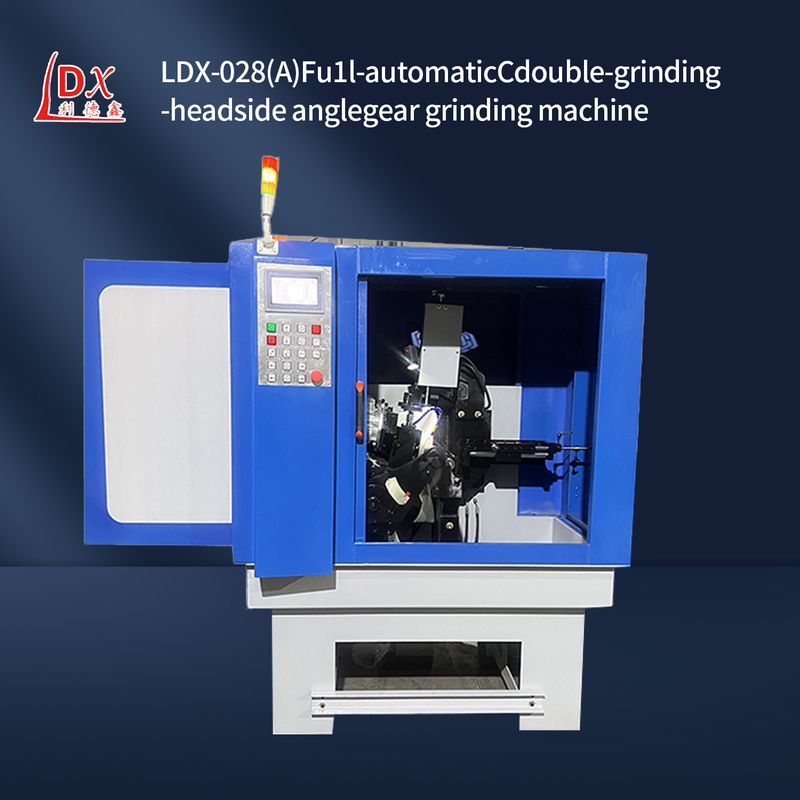

LDX-028A Guangdong CNC Servo Saw Blade Double Grinding Head Side Angle Grinding Machine

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-028A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Outer diameter dimensions: 1.75*1.4*2.0mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Operating Speed: | 18 Teeth/min | Feeding Stroke: | 1-28mm (stepless Variable Speed) |

|---|---|---|---|

| Grinding Wheel Dimensions: | 80*100*32mm | Thickness Of Saw Web (steel Plate): | 1-7mm |

| Aw Web Bore Diameter: | 12-220mm | Total Power: | 4.3KW |

| Highlight: | Double Grinding Head Grinding Machine,Saw Blade Double Head Grinding Machine |

||

Product Description

LDX-028A Guangdong CNC Servo Saw Blade Double Grinding Head Side Angle Grinding Machine

The market competitiveness of the saw blade grinding machine of Lidexin Machinery Manufacturing Co., Ltd. is mainly reflected in the following aspects:

1,High-precision machining: The equipment adopts advanced numerical control technology and precision mechanical structure, which can ensure the grinding accuracy of the saw blade, so that the parameters of the saw blade tooth shape, Angle and so on can achieve high accuracy, so as to ensure the cutting accuracy and efficiency of the saw blade in use. For example, when machining complex tooth shapes or saw blades with high precision requirements, the company's gear grinding machines are able to achieve high precision grinding steadily.

2,Efficient grinding ability: With high grinding speed and feed speed, the saw blade can be completed in a short time to improve production efficiency. For enterprises that mass-produce saw blades, this efficient processing capacity can reduce production costs and improve the competitiveness of enterprises.

3,Good stability and reliability: the machine can maintain stable performance during long-term operation and reduce the probability of failure. This means that enterprises can reduce the downtime and maintenance costs caused by equipment failure and ensure the continuity of production when using Lidexin's saw blade grinding machine.

4,Rich product line: The company provides a variety of models and specifications of saw blade grinding machines, to meet the needs of different customers for saw blade grinding. Whether it is a small woodworking blade, or a large industrial saw blade, you can find the corresponding grinding machine number.

5,Customized service: We can provide customized gear grinding machine products and solutions according to the special needs of customers. For example, for some saw blades with special tooth shape requirements or special size requirements, Lidexin can design and produce according to customer requirements to meet customer's individual needs.

6,Continuous research and development investment: The company focuses on technology research and development, and constantly invests funds and manpower to develop new products and improve existing products. Through cooperation with universities and scientific research institutions, we constantly introduce new technologies and concepts to improve the technical level of products.

7,Intelligent technology application: the intelligent technology is applied to the saw blade grinding machine, such as automatic control system, intelligent diagnosis system, etc. The automatic control system can realize the automatic control of the grinding process and improve the machining efficiency and precision. The intelligent diagnosis system can monitor the running status of the equipment in real time, discover and solve the potential problems in time, and reduce the maintenance cost of the equipment.

8,Years of industry experience: The company has many years of production experience in the field of saw blade grinding machine, and has accumulated rich technical and management experience. Through continuous optimization of products and services, we have won the trust and praise of customers and established a good brand image.

| Technical parameters: |

| Saw web machining diameter range:¢100-¢800mm |

| Saw web bore diameter: 12-220mm |

| Thickness of saw web (steel plate):1-7mm |

| Tooth pitch: 5-80mm |

| Front inclination angle, inclination angle: 5°-15° |

| Radial angle: 3°-15° |

| Operating speed: 18 teeth/min |

| Feeding stroke: 1-28mm (stepless variable speed) |

| Grinding wheel dimensions: 80*100*32mm |

| Grinding speed: 26m/s |

| Coolant pump flux: 501/min |

| Coolant cylinder volume: 90L |

| Total power: 4.3KW |

| Voltage: Three-phase 380v |

| Weight: 1,100KG |

| Outer diameter dimensions: 1.75*1.4*2.0mm |

| Technical characteristics: |

| An intuitive and simple whole Chinese operation interface is matched with a large-sized touch screen, so the equipment is easier to operate, and all preset procedures or self-compiled procedures are more convenient to call; the servo tool setting device features accurate positioning, so the product grinding accuracy is greatly ensured. Due to the adoption of high-quality and high-accuracy castings and machined parts, the service life of the equipment is greatly prolonged, and the equipment is simple and easy to operate and maintain; one person can operate many pieces of equipment at the same time, so the production efficiency is greatly improved, and the cost is reduced. |

![]()

![]()

![]()

![]()