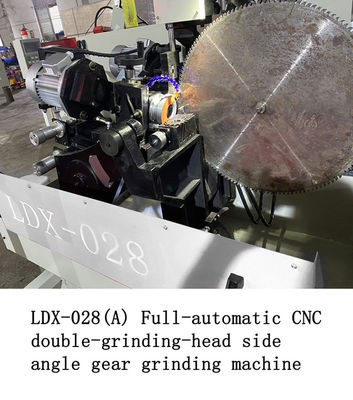

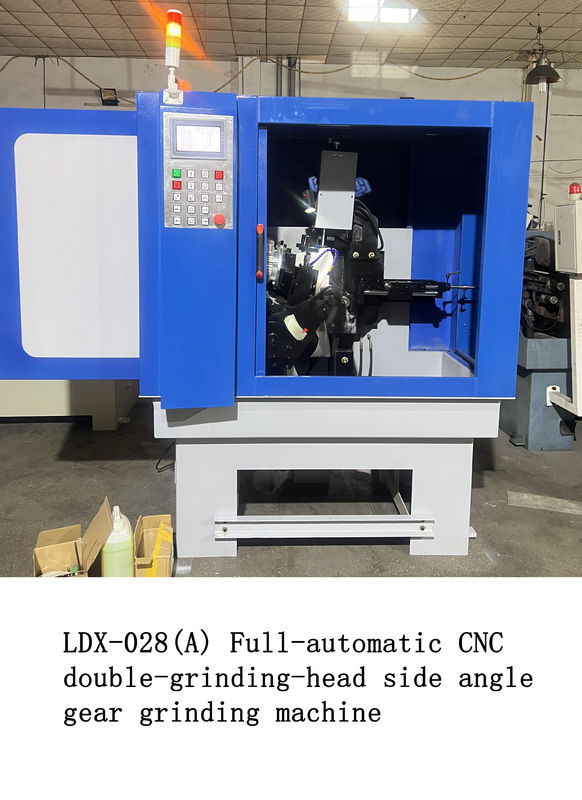

LDX-028A Full Servo CNC Double Grinding Head Side TCT Saw Blade Grinding Machine

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-028A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Outer diameter dimensions: 1.75*1.4*2.0mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Feeding Stroke: | 1-28mm (stepless Variable Speed) | Coolant Pump Flux: | 501/min |

|---|---|---|---|

| Total Power:: | 4.3KW | Grinding Wheel Dimensions: | 80*100*32mm |

| Highlight: | 1-28mm tct saw blade grinding machine,1-28mm 4 inch saw blade for grinder,servo tct saw blade grinding machine |

||

Product Description

LDX-028A Full servo CNC double grinding head side TCT saw blade grinding machine

Operation process:

1,1 mode A

2,Manually set the knife, enter the number 5 on the left and right, that is, add 5 wires on the left and right, and there are 10 wires in total.

3,Mode A twice

4,Manually set the good knife, left feed 1, 21 (5) (10) The first knife grinds 5 wires, the second knife grinds a total of 10 wires, and the second knife is superimposed.

| Technical parameters: |

| Saw web machining diameter range:¢100-¢800mm |

| Saw web bore diameter: 12-220mm |

| Thickness of saw web (steel plate):1-7mm |

| Tooth pitch: 5-80mm |

| Front inclination angle, inclination angle: 5°-15° |

| Radial angle: 3°-15° |

| Operating speed: 18 teeth/min |

| Feeding stroke: 1-28mm (stepless variable speed) |

| Grinding wheel dimensions: 80*100*32mm |

| Grinding speed: 26m/s |

| Coolant pump flux: 501/min |

| Coolant cylinder volume: 90L |

| Total power: 4.3KW |

| Voltage: Three-phase 380v |

| Weight: 1,100KG |

| Outer diameter dimensions: 1.75*1.4*2.0mm |

| Technical characteristics: |

| An intuitive and simple whole Chinese operation interface is matched with a large-sized touch screen, so the equipment is easier to operate, and all preset procedures or self-compiled procedures are more convenient to call; the servo tool setting device features accurate positioning, so the product grinding accuracy is greatly ensured. Due to the adoption of high-quality and high-accuracy castings and machined parts, the service life of the equipment is greatly prolonged, and the equipment is simple and easy to operate and maintain; one person can operate many pieces of equipment at the same time, so the production efficiency is greatly improved, and the cost is reduced. |

![]()

![]()

![]()

![]()