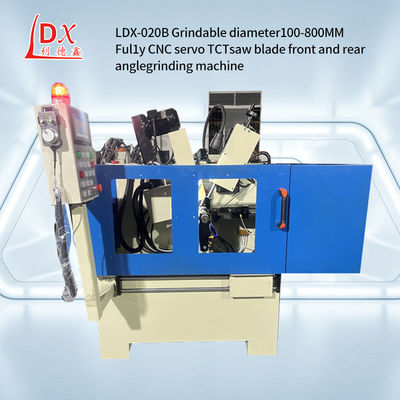

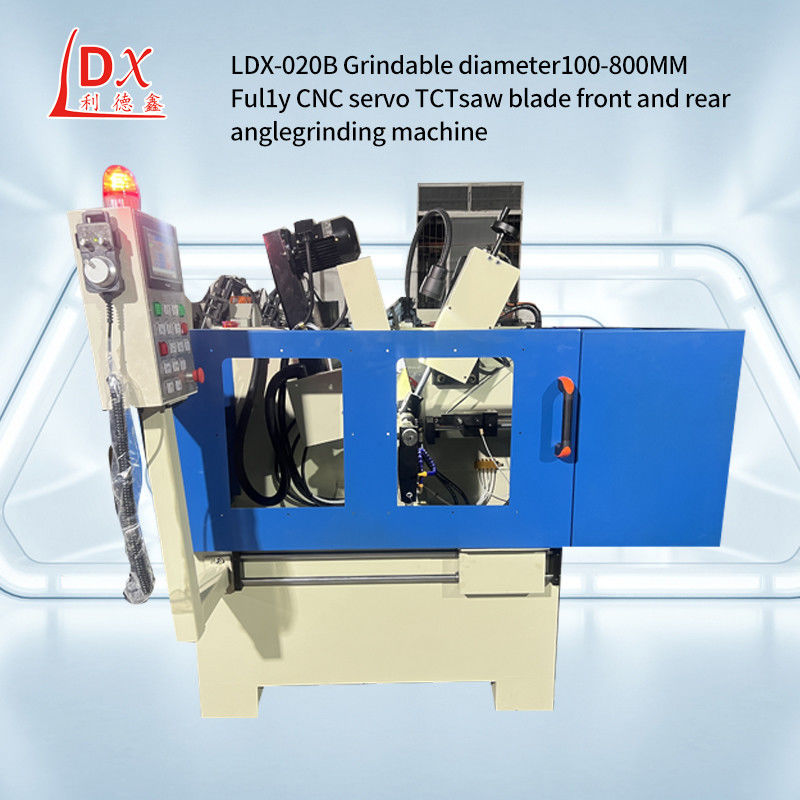

LDX-020B Fully Automatic Swing Angle Circular Saw Blade Grinding Machine Manufacturer

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-020(B) |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Mechanical size (length X width X height): 1500X1300X1800mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Sharpening Speed: | 0.5-6mm/s | Working Speed: | Max. 20 Teeth/min |

|---|---|---|---|

| Mechanical Weight: | 710KG | Processing Saw Blade Diameter Range: | ¢100-800mm |

| Tooth Surface Angle: | 5 Degrees ~ +30 Degrees | ||

| Highlight: | Fully Automatic Saw Blade Grinding Machine,Swing Angle Saw Blade Grinding Machine |

||

Product Description

LDX-020B Fully automatic swing angle circular saw blade grinding machine manufacturer

Saw blade grinding the best method:

1,Machine grinding. A professional saw blade sander is required. Install the saw blade on the machine

2,Adjust the grinding Angle and speed. Start the machine and start grinding, making sure the serrations grind evenly.

3,Use a finer grinding wheel for polishing, so that the surface of the saw blade is smooth, and finally wipe it clean with a rag.

What angle should the saw blade be sharpened? Selection of saw tooth angle:

1,The angle parameters of the sawtooth part are relatively complex and the most professional, and the correct selection of the angle parameters of the saw blade is the key to determining the quality of sawing. The most important angle parameters are rake angle, back angle and wedge angle.

2,The rake angle mainly affects the force consumed in sawing wood chips. The larger the rake angle, the better the cutting sharpness of the saw teeth, the lighter the sawing, and the easier it is to push the material. Generally, when the material to be processed is soft, choose a larger rake angle, otherwise choose a smaller rake angle.

| Technical Parameters: |

| Processing saw blade diameter range: ¢100-800mm |

| Saw blade aperture: ¢10-220mm |

| Saw blade thickness (steel plate): 1-7mm |

| Pitch: 7-100mm |

| Tooth surface angle: 5 degrees ~ +30 degrees |

| Tip back angle: 6-45 degrees |

| Left and right inclination of the tooth: tooth top / tooth surface 45 degrees |

| Sharpening stroke range: up to 25mm (adjustable) teeth / minute |

| Sharpening speed: 0.5-6mm/s |

| Working speed: maximum 20 teeth / minute |

| Grinding wheel size (outer diameter x hole): (¢125mmx¢32mmX1mm) |

| Negative chamfer grinding: -27 degrees |

| Grinding head can rotate angle: 90 degrees and 180 degrees |

| Grinding wheel line speed: 26m / s |

| Coolant pump flow: 501/min |

| Cooling tank volume: 85L |

| Total power: 1.85 kW |

| Voltage: three-phase 380v |

| Mechanical weight: 710KG |

| Mechanical size (length X width X height): 1500X1300X1800mm |

| Technical features: |

| This machine is designed in reference to the features of domestic and foreign similar types, which absorbs and analyzes the advantages of the same type and improves the functions to some extent at the same time. |

| 1. Preset many groups of tooth types and one-key multifunctional operation. |

| 2. Trapezoid flat teeth can be finished at a time, features CNC grinding and arbitrary tooth types, and can improve the efficiency by 3 times; due to the adoption of improved tooth extraction operation, the accuracy is improved, and the service life is prolonged. |

![]()

![]()