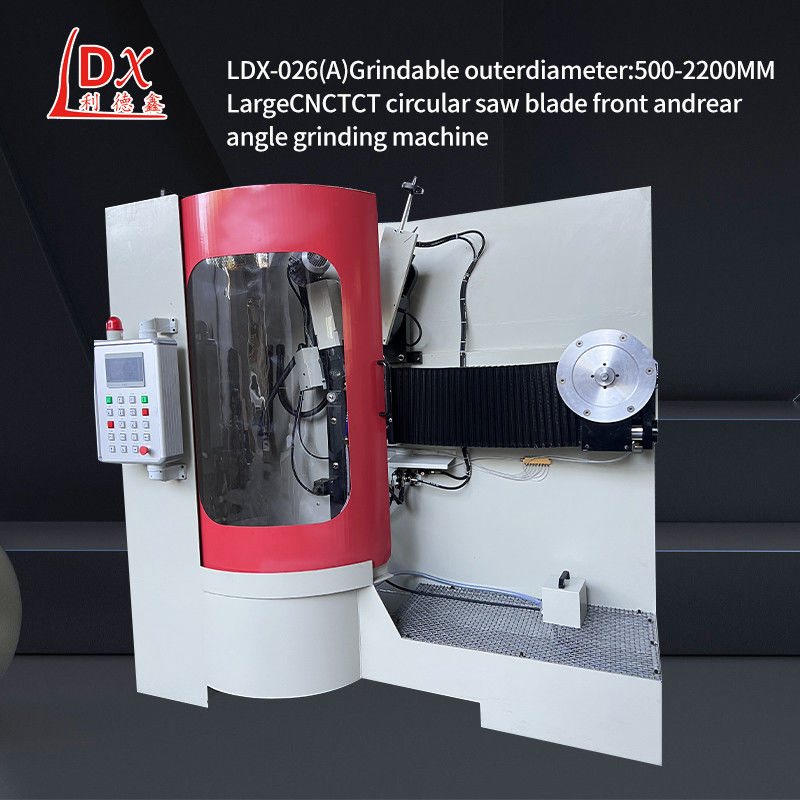

LDX-026A Large Circular Saw Blade Sharpening Machine Manufacturers

Product Details:

| Place of Origin: | Foshan, Guangdong, China |

| Brand Name: | Lidexin |

| Certification: | CU,ISO |

| Model Number: | LDX-026A |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | Western Union |

| Packaging Details: | Mechanical dimensions (length x width x height): 1900X1400X2000mm |

| Delivery Time: | 10-15 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100pcs/mon |

|

Detail Information |

|||

| Processing Saw Blade Diameter Range: | ¢500- ¢ 2200mm | Saw Blade Aperture: | ¢ 10-220mm |

|---|---|---|---|

| Mechanical Dimensions (length X Width X Height): | 1900X1400X2000mm | Grinding Wheel Linear Speed: | 26m/s |

| Voltage: | Three-phase 380v | Saw Blade Thickness (steel Plate): | 1-12mm |

| Highlight: | Large Circular Saw Blade Sharpening Machine,Circular Saw Blade Sharpening Machine Manufacturers |

||

Product Description

LDX-026A Large circular saw blade sharpening machine manufacturers

Saw blade grinding machine material which is better:

1,Compared with carbon tool steel, alloy tool steel has good heat resistance, good wear resistance and better processing performance, and the heat deformation temperature is 300℃-400℃ suitable for manufacturing alloy circular saw blades.

2,High speed tool steel has good hardenability, strong hardness and rigidity, less heat resistance and deformation, is ultra-high strength steel, thermoplastic stability suitable for manufacturing ultra-thin saw blades.

CNC circular saw blade grinding machine suitable for what industry:

1,The shipbuilding industry in the processing of special, large gear, box and gantry gear equipment components, may need to use CNC gear grinding machine, including some specific models of circular saw blade grinding machine. Its highly accurate geometric precision machining capabilities play an irreplaceable role in navigation and control equipment.

2,n addition, CNC circular saw gear grinding machine may also play a role in telecommunications equipment manufacturing, machinery manufacturing and other fields. In short, any industry that requires the use of circular saw blades for cutting is likely to benefit from the efficient and precise grinding capabilities of CNC circular saw gear grinding machines.

3,It should be noted that the specific needs and configurations of CNC circular saw grinding machines in different industries may vary. In the selection and use of CNC circular saw gear grinding machine, it is necessary to consider according to the actual needs and industry characteristics to ensure that the equipment can meet the production requirements and maximize the benefits.

| Technical parameters: |

| Processing saw blade diameter range: ¢500- ¢ 2200mm |

| Saw blade aperture: ¢ 10-220mm |

| Saw blade thickness (steel plate): 1-12mm |

| Tooth pitch: 7-120mm |

| Tooth surface angle: 5 degrees to+30 degrees |

| Tooth top back angle: 6-45 degrees |

| Left and right inclination of teeth: tooth tip/tooth surface 45 degrees |

| Blade grinding stroke range: maximum 25mm (adjustable) teeth/minute |

| Grinding speed: 0.5-6mm/s |

| Working speed: maximum 20 teeth/minute |

| Grinding wheel size (outer diameter x hole): (¢ 125mm x ¢32mmX1mm) |

| Negative chamfer grinding: -27 degrees |

| Grinding head rotatable angle: 90 degrees and 180 degrees |

| Grinding wheel linear speed: 26m/s |

| Flow rate of coolant water pump: 501/min |

| Volume of coolant cylinder: 85L |

| Total power: 2.2 kW |

| Voltage: three-phase 380v |

| Mechanical weight: 1200KG |

| Mechanical dimensions (length x width x height): 1900X1400X2000mm |

| Technical features: |

| The design of this machine refers to the characteristics of similar domestic and foreign models, absorbs and analyzes the advantages of the same type, and makes some functional improvements. This equipment is specifically designed for grinding large alloy saw blades. |

| 1. Pre set multiple sets of tooth profiles for one click multifunctional operation. |

| 2. The flat teeth of the ladder can be completed in one go, with CNC grinding and any tooth shape, which can increase efficiency by three times; Improved gear extraction operation to improve accuracy and extend service life. |

![]()

![]()

![]()